Inside BENEO’s new pulse plant: pioneering sustainable protein from faba beans

The hose is compatible with many food product types such as dairy, beer, wine, and spirits

Versilon™ XFR is the first hose with full FDA food contact compliance. Questioning if testing only the food contact layer was enough to ensure the safety of the consumer, French firm Saint-Gobain tested the compliance of Versilon XFR hose as a whole rather than only its inner food contact layer.

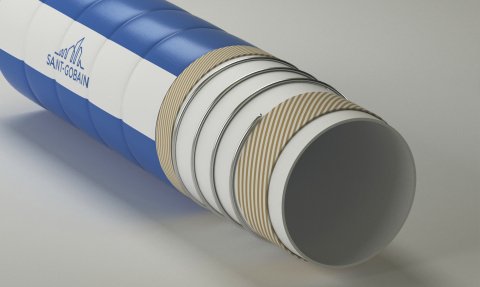

Hoses are used in the Food & Beverage processing industry for a variety of loading and transfer applications. To achieve the desired performance, the hose is commonly constructed with a relatively complicated layer structure.

These structures include an inner liner (in direct contact with food), one or more reinforcement layers, and an outer jacket layer (to reduce wear and tear), sometimes resulting in upwards of 7 or more layers. These hoses are regulated by the FDA, as the chemicals from the food contact layer could migrate into the transferred food or beverages and pose adverse health risks.

Launched last year, Versilon XFR is a lightweight, suction and discharge hose designed for food and beverage transfer applications. Lighter than traditional suction and discharge hoses, Versilon XFR has excellent flexibility to facilitate pump and tank attachment. The hose is compatible with many food product types such as dairy, beer, wine, and spirits.