Inside BENEO’s new pulse plant: pioneering sustainable protein from faba beans

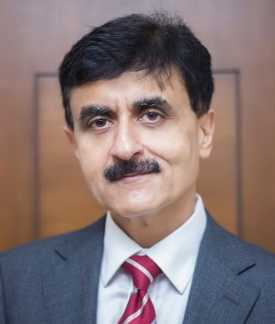

Thermo Fisher Scientific, the world leader in serving science, is on a mission to enable its customers to make the world healthier, cleaner and safer. The company is driving innovation in multiple disciplines and food safety is a priority area. In conversation with nuFFooDS Spectrum, Amit Chopra, Managing Director, India and South Asia, Thermo Fisher Scientific, talks about the company’s role in driving sustainability and food safety in India. Edited excerpts-

How can we ensure a sustainable food safety management system in India?

A healthy population is an enabler of a healthy economy. In a country where the burden of food-borne illnesses is comparable to malaria, HIV and TB, food safety is a priority. It is estimated that every year 100 million cases of food-borne diseases are reported in India, a number expected to rise by 50 per cent by 2030. To ensure availability of safe and hygienic food, effective food testing measures are important at every step across the value chain, including agriculture, processing, packaging, labelling and delivery.

First, it is important to deploy strategies to maximise crop productivity while minimising use of pesticides. Second, targeted policies can ensure the efficient use of energy and curtail emissions during food processing. Third, food testing and quality checks are imperative to ensure food safety during packaging, labelling and delivery.

Food Safety and Standards Authority of India (FSSAI) is implementing a Central Sector Scheme for ‘Strengthening of the Food Testing Ecosystem’ in the country with provisioning of modern testing equipment in State Food Testing Laboratories (SFTLs), as well as allocating Mobile Food Testing Labs.

Thermo Fisher Scientific is playing a pivotal role in enhancing food testing with its state-of-the-art technologies such as LCMS/MS, ICPMS, GCMS/MS, products for microbiological testing and sample preparation reagents.

Various other initiatives by FSSAI, such as inspection via digital tools, ensures food safety management even at grass-root levels. Programmes such as ‘Eat Right India’ have been devised to spread awareness among consumers on the importance of healthy eating. Thermo Fisher Scientific has been actively partnering with FSSAI for the same.

What are the major challenges being faced in this area?

The World Health Organization (WHO) lists food-borne diseases in South-east Asia, including India, as the leading cause of mortality in those regions, with more than 40 per cent of the cases among children younger than five. Food fraud and adulteration are rampant in India and occur at all points of the food supply chain. Milk, honey and spices are common sources of adulteration.

A shift in consumer preference towards ready-to-use foods, especially post COVID-19, has led to the mushrooming of many unregulated enterprises and food imports from different sources. This has made adherence to food safety protocols challenging, considering the large scale of operations.

Insufficient number of labs in the country is a challenge, considering our vast population. The FSSAI has initiated a scheme to provide mobile units for food testing to states. These units not only address the lack of food testing infrastructure in the most remote areas, but also cater to the basic analytical needs of the consumers.

What role do ‘food testing labs’ play in ensuring sustainable food production?

Food testing labs are aiding consumers and regulatory authorities to testify that the products are manufactured by standard practices. The objective of food testing labs is to ensure that the food is free from various hazards such as:

Biological: Derived from microbial sources such as salmonella and E. coli bacteria.

Chemical: Contamination with chemicals used in agriculture and production processes of raw materials such as antibiotics, plant-growth substances and pesticides, as well as food-additives such as preservatives.

Physical: Foreign objects in food such as glass, pieces of metal, plastic or wood.

Implementing stringent measures to check for discrepancies in labelling, is another major role played by the food testing labs to ensure safe food.

Increasing number of tests like allergen tests, food intolerance and checking for adulterants, are the major factors driving the growth of the Indian food-testing market. Valued at $14 million in 2018, the market is expected to grow at a CAGR of 11.3 per cent to $26.4 million by 2024.

As per a study by the Ministry of Food Processing Industries in 2020-21, the country has 726 testing labs, of which 585 are accredited according to international standards.

In the past few years, FSSAI has taken cognizance of the need to invest in various State Food Testing Laboratories to strengthen the infrastructure.

How is Thermo Fisher working in this direction of sustainability & food safety in India & globally?

A rapidly growing population is leading to an increased demand for mass production and distribution of food, through a complex system involving many suppliers. Every step of the food-chain cycle requires intervention to prevent food-fraud and adulteration.

We drive innovation in multiple disciplines, and food-safety is a priority area. Our advanced food-testing workflows comprise products and expertise, from identification of species in food and ingredients, to verification of origin, traceability of raw materials and cleaning processes in production lines.

Traditional methods of lab-based testing are designed to identify and quantify a known substance only, apart from having a lengthy turnaround time. One of the recent approaches, Next-generation sequencing (NGS), allows untargeted detection of thousands of species of organisms, eliminating the need for previous knowledge of the species. Thermo Fisher Scientific’s NGS is one of the leading testing methods applied to detection of food-fraud, especially in herbs and spices.

India is the largest producer of milk in the world, making it one of the easiest targets for food adulteration. Milk is often contaminated with pesticide residues, veterinary medicines, and aflatoxin M1. Each of these groups of compounds use specific extraction protocols, which require different methods to detect, thus increasing analysis time, turnaround time, and cost of analysis. To address these challenges, we have developed a generic approach for the simultaneous extraction of these contaminants, followed by a single combined LC-MS/MS analysis.

Milk or milk products are also adulterated with vegetable oil or other animal fat (e.g., lard from pork) in ghee. Our teams have developed methods both on GC-FID system- Triglycerides-based as well as on HPLC by using β-Sitosterol in compliance with the recent regulatory guidelines to support various dairy plants/ industry.

The biggest challenge with seafood testing is the turnaround time at every step of the testing cycle. Our ready-to-use culture media reduces the time for sampling. Our qPCR workflows streamline processes for pathogen detection, including surface sampling for environment monitoring. Thermo Fisher Scientific’s Next Generation Food Authenticity workflow is an application that can identify and trace numerous seafood species.

In India, Thermo Fisher Scientific has set-up the Food Safety Solution Centre at Ghaziabad, in collaboration with FSSAI. The centre focuses on development, training and support for next-generation workflows and integrated solutions across chromatography and mass spectrometry. Additionally, training programmes are conducted for food analysts for method optimisation/developing new methods for FSSAI and extending their expertise, wherever required.

Through the COVID-19 pandemic, our team worked relentlessly and conducted more than 50 webinars in collaboration with FSSAI for creating awareness and supporting food-testing labs with advanced workflows/ solutions.

Will you be launching new products or planning new investments in this space?

We are constantly enhancing our capabilities to support the world with new and advanced scientific solutions. We recently launched our new GCMS/MS system TSQ 9610 and Delta Q-IRMS system for honey testing. Other exciting products are in the development stage and will be launched soon.