Inside BENEO’s new pulse plant: pioneering sustainable protein from faba beans

Engineered for the high-volume, efficient production of Flour Tortilla, Burrito, Plain Paratha, and Lachha Paratha

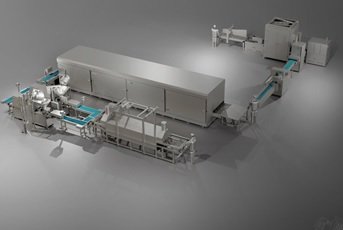

ANKO Food Machine has launched four new integrated production lines specifically engineered for the high-volume, efficient production of Flour Tortilla, Burrito, Plain Paratha, and Lachha Paratha.

The complete system integration covers every stage, with tooling flexibility designed to support regional variations and recipe-specific adjustments. ANKO’s lines can precisely handle complex tasks such as pressing and cooking flour tortillas, folding burrito wraps, layering fluffy 36-layer parathas, or curling laccha parathas into their signature spirals.

By integrating key processes like dough feeding, forming, and inspection into a single system, ANKO offers producers transitioning from legacy equipment to modern technologies a new way to reimagine food production—with the assurance that traditional methods are still respected. Dough resting units allow gluten to develop the proper elasticity and give oil time to solidify before rolling. Environmental sensors provide feedback to plant managers, confirming that temperature and humidity levels are optimal for every step of the process.

ANKO has integrated robot arms, metal detectors and X-ray quality control systems at the back end to improve the precision and reliability of products and inspection, enhancing food safety by detecting foreign objects or inconsistencies, and organizing finished products more efficiently. Robot-assisted packing reduces human handling, boosts hygiene, and supports smoother flow in downstream logistics.