Inside BENEO’s new pulse plant: pioneering sustainable protein from faba beans

In the case of packaging, there is always the question of sealing seam quality. Flo-ir GmbH has developed sealed seam with a robust measuring technique for industrial use.

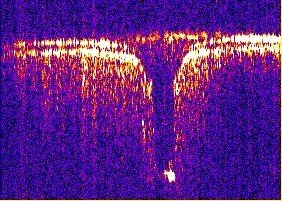

The system allows checking the seal seam in micrometer accuracy at high test speed. It can detect even a hair in sealed seam.

In contrast to all conventional systems for sealing seams, this system provides clear information about the quality of the seal seam in the current production. It can also find a hair as well as oil sprays, wrinkles, cold-weld seams and so on.

Independent of the coating material, system provides information, even when it comes to the porosity in the seal seam. Whether or not an opaque film protects the product or a transparent film, a container with a sealed surface in a clear box or with a transparent cover, a cup-lid or aluminum can play no role.

With the latest technology, it is possible to monitor and inspect sealing processes much better than the past. Considering that light is traveling at a speed of 300,000 km per second, one can imagine that a sealed seam and the entire surface of a food bag can be inspected completely in a fraction of a second.

With the new inspection system, food bags are fully inspected at a resolution of 100 microns so that defects in the seal seam, micro holes or delamination are already detected during production.

The information “Seal seam inspection, delamination and micro hole detection” shows how the seal seam inspection of the future looks like.