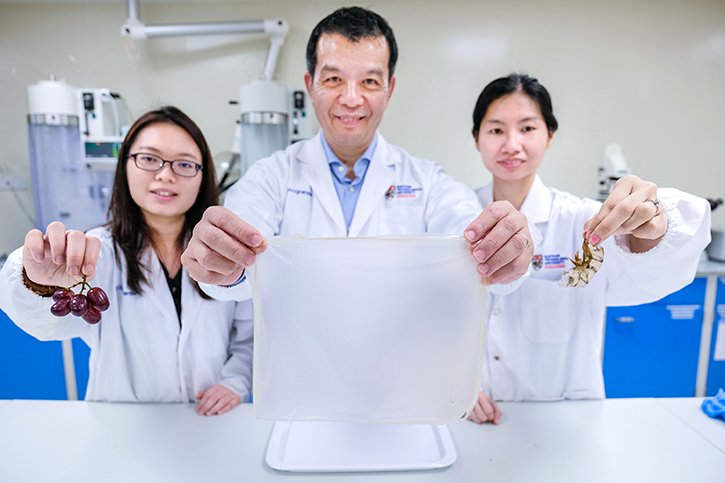

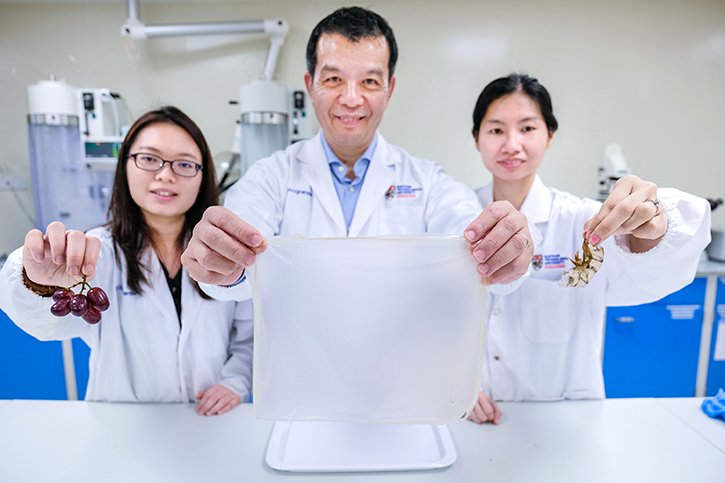

NTU developed a green way to create chitin, by using two forms of food waste

Scientists at Nanyang Technological University, Singapore (NTU Singapore) have developed a green way to create chitin, by using two forms of food waste – prawn shells and discarded fruit – and fermenting them.

Chitin serves a wide variety of uses in the food industry, such as food thickeners and stabilisers, and as anti-microbial food packaging.

The NTU method is more sustainable than current approaches that chemically extract chitin from marine waste, which is costly, consumes large amounts of energy and leads to chemical by-products that may be discharged in industrial wastewater.

The NTU team tested ten sources of common fruit waste such as white and red grape pomace, mango and apple peels, and pineapple cores, in various fermentation experiments. They found that fruit waste contained enough sugar content to power the fermentation process that breaks prawn shells down into chitin.

They used ‘X-ray diffraction’ technique to determine the atomic and molecular structure of the chitin created using the new method and its level of purity was measured using a ‘crystallinity index’. The extracted crude chitin samples from prawn shells fermented using fruit waste gave a crystallinity index of 98.16 per cent, which compared to commercial chitin samples with an index of 87.56 per cent. The fermentation process using the sugar content from the fruit waste produced higher quality chitin than the commercial one.

The NTU team is now exploring ways to use chitosan to enhance previous research innovations such as food packaging created using soybean residue or Okara. This could potentially lead to the development of a more durable cellulose film with anti-microbial and anti-bacterial properties.