Inside BENEO’s new pulse plant: pioneering sustainable protein from faba beans

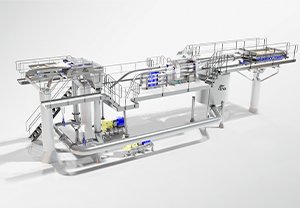

The integral ‘switcher’ first-hand, which enables the hydro-cutting system to easily deliver against the industry’s highest output capacity

TNA solutions has revealed its latest innovation in french fries processing, delivering greater efficiency, flexibility and consistency. The new tna conti cut hydro cutting system, with cutting-edge ‘switcher’ technology, was unveiled at TNA solutions’ stand at Anuga FoodTec 2024. The integral ‘switcher’ first-hand, which enables the hydro-cutting system to easily deliver against the industry’s highest output capacity (approx. 30 Mt/hr).

“With the global french fries market set to grow to over $40bn in terms of value by 20271, our customers require solutions that deliver maximum capacity and the highest levels of efficiency and uptime,” said Twan van den Berg, Global Sales Manager Processing at TNA solutions. “The new tna conti cut has been designed to deliver against this incredible market growth, and we are proud to be displaying the innovative switcher alignment and cutting technology here at Anuga FoodTec.”

Switcher technology within the tna conti cut® delivers many benefits:

· Drive efficiency, and productivity, reduced waste and uptime with designated alignment tubes and integrated knife blocks. Both are exchangeable, depending on the final product to be processed and the potato size used.

· Achieve the longest cut size possible when processing potatoes in high volumes through the alignment tubes.

· Add flexibility with an interchangeable knife block, enabling potatoes to be cut into different shapes and sizes, such as: sticks, wedges, and slices.

· Guarantee a smooth cutting surface with the tna conti-cut® hydro cutting system, resulting in less oil pick up compared to a mechanically cut surface, reducing oil usage and fat content.