Inside BENEO’s new pulse plant: pioneering sustainable protein from faba beans

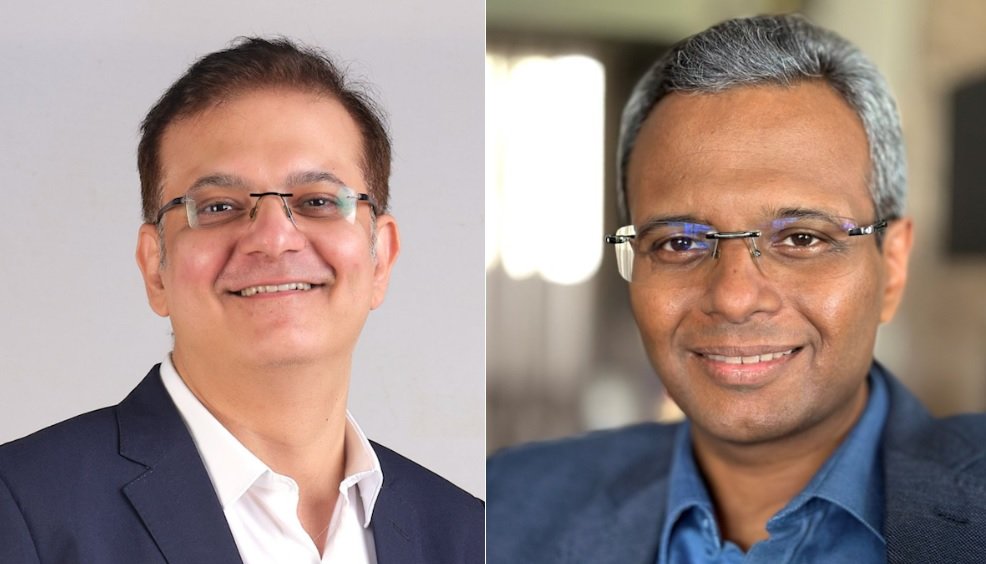

Cargill and McCain have recently strengthened their decades-long partnership to advance sustainable and science-led innovation in this space. Together, they are working on next-generation product solutions, responsible sourcing and supporting the growth of India’s quick service restaurant (QSR) and frozen foods ecosystem. Dheeraj Talreja, Vice President and Managing Director, Food South Asia, Cargill and Mainak Dhar, Managing Director, McCain Foods India, talk about how the frozen food sector is evolving, the growth drivers and challenges. Edited excerpts;

How big is the frozen food sector in India?

Talreja: India’s frozen potato food segment, especially French fries and specialty potato products, is among the fastest-growing parts of the overall frozen foods market. The category is currently growing at approximately 11 per cent CAGR, driven by rising affluence, increasing exposure to changing food habits, and the rapid expansion of QSRs and online food delivery platforms.

India’s strong macro-economic fundamentals further support this growth. With GDP growing at over 6 per cent annually and nearly 50 per cent of the population expected to enter the high- and upper-middle-income bracket by 2030 (earning over $8,500 per capita), the consumption of convenience and premium food formats is expected to rise sharply. At the same time, the growing digital penetration, with nearly one billion Internet users expected by 2030, is accelerating awareness and

aspiration for global food brands and cuisines.

What are the growth drivers and challenges being faced by the frozen food sector in India?

Talreja: The strongest growth drivers are affluence, aspiration and accessibility. Higher disposable incomes are encouraging consumers to trade up to branded, high-quality frozen foods. Digital connectivity and global exposure are driving preference for Western-style foods, especially among younger consumers. Most importantly, the rapid growth of QSRs, cafés and cloud kitchens is a key catalyst, with QSRs and cloud kitchens expected to grow at a CAGR of over 17 per cent between 2025 and 2030, according to Swiggy–Kearney’s How India Eats 2025 report — significantly boosting demand for frozen potato products like French fries.

Challenges remain around uneven cold-chain infrastructure, energy and logistics costs, and lingering consumer misconceptions around frozen foods.

However, these are being steadily addressed through investments in storage, transport, retail freezers and consumer education. How do you ensure food safety and quality?

Dhar: McCain follows a fully integrated “seed-to-shelf” food safety system. This includes contract farming, seed development, agronomy support, controlled harvesting, cold storage, traceability and world-class manufacturing practices. Our plants operate under globally recognised food safety and quality certifications and undergo routine audits. Each product batch is tested for microbiological, chemical and physical parameters to ensure it meets McCain’s global standards.

Talreja: From a Food Safety, Quality, and Regulatory (FSQR) standpoint, McCain has consistently rated Cargill an ‘A’ over the past four to five years, awarding a 99.6 per cent score for SG Palm Olein, recognising right-first-time quality against McCain’s specifications and sustained RSPO certification. This certification covers incomingcompliance, food safety, and quality compliance, as well as regulatory documentation and compliance.

Generally, Cargill’s global quality management system (QMS) is implemented across its plants to support consistent product quality and food safety management. Our product safety, quality, and regulatory policy outlines the requirements that guide our approach to providing safe, quality products. Cargill India plants hold Food Safety System Certification (FSSC) 22000 certification from a United Kingdom Accreditation Service (UKAS)-registered certification body, reflecting the application

of internationally recognised food safety management systems, including Hazard Analysis and Critical Control Points (HACCP) and Prerequisite Programmes.

Who are your major suppliers?

Our primary raw material, potatoes, is sourced through a contract farming network across India’s major potato belts. We also work with approved and audited suppliers for oils, coatings, seasonings, packaging and logistics, ensuring compliance with McCain’s global standards on quality, safety, ethics and sustainability.

What kind of tech innovations are currently being used at your plants to ensure zero adulteration and a better supply chain mechanism?

Dhar: Our manufacturing plants use advanced optical sorters, defect scanners, metal detectors and foreign-matter detection systems to ensure product integrity. Digital traceability systems allow us to track raw material and finished goods through every stage of production and distribution. Automation and data analytics help optimise yields, reduce waste and improve consistency.

Talreja: Cargill applies its product safety, quality and regulatory policy to support product risk assessment and mitigation across sourcing, manufacturing, and the supply chain. This is complemented by a Supplier Qualification Management programme designed to identify and mitigate food safety, quality, and regulatory risks. In addition, Cargill plants utilise advanced testing equipment such as Gas Chromatography and Inductively Coupled Plasma (ICP) to support robust analytical and instrumental capabilities for adulteration testing.

Tell us about the sustainability measures being followed and anything planned for the future.

Dhar: McCain works with farmers on regenerative farming practices, responsible irrigation, soil health and crop optimisation. At our plants, we focus on reducing water and energy intensity, increasing renewable energy use, improving waste management and moving toward more sustainable packaging. These efforts align with McCain’s global commitments to regenerative agriculture, climate action and resource efficiency.

Talreja: Cargill operates at the centre of the global food system, connecting farmers, food producers, and consumers while advancing more sustainable food production. Our sustainability approach focuses on three priorities – Climate, Land and Water, and People, supporting practices that help reduce emissions, protect natural resources, and strengthen farmer and community livelihoods to build more resilient food systems. These priorities guide how we operate across our sites and supply chains and shape how we work with partners to strengthen responsible sourcing over time.

Read our 2025 Environmental, Societal, and Governance (ESG) report for more detailed information. In practice, this is reflected in Cargill’s support for McCain’s transition to more sustainable palm oil sourcing, including the adoption of RSPO Segregated palm oil, helping establish McCain as an early adopter in India. Cargill sites are also Sedex SMETA 4-Pillar certified, demonstrating alignment with recognised standards for ethical, social, and environmental responsibility. Looking ahead, Cargill continues to collaborate with partners to further strengthen responsible sourcing and sustainability practices.

What are the future plans in the pipeline?

Dhar: India continues to be a strategic growth market for McCain. We are investing in expanding capacity,

deepening farmer partnerships, broadening our product portfolio and strengthening our national distribution

across retail and food service channels.

Talreja: We aim to continue strengthening our presence in India as a customer-focused and responsible growth partner, building on existing capabilities and partnerships. Our focus is on expanding solutions tailored to local market needs, while deepening technical collaboration and co-creation with customers. This approach is supported by efforts to connect the

right solutions with the right customers, enable faster innovation, deliver seamless service, and advance sustainability-led capabilities. Through these efforts, Cargill seeks to support customer success and grow alongside India’s evolving food landscape.

Sanjiv Das

sanjiv.das@mmactiv.com