Inside BENEO’s new pulse plant: pioneering sustainable protein from faba beans

Food adulteration has long been a significant concern in India. High-profile cases involving Nestle’s Maggi noodles and honey from established Indian brands such as Dabur and Patanjali are among the most controversial, sparking public outrage. In response, regulatory bodies such as the Food Safety and Standards Authority of India (FSSAI), and the Food and Drug Administration (FDA) have been actively improving laboratory standards and developing new initiatives for the efficient functioning of food testing labs. In this article, we will examine the efforts being made by food regulators in India to revamp the food testing systems and how the industry is responding to these efforts.

Food safety has always been a critical issue in India, with the country’s food testing laboratories facing a range of controversies from poor infrastructure to under-skilled manpower. One particular point of contention relates to the in-house food testing facilities of various Food Business Operators (FBOs). This practice raises conflicts of interest, as the labs are located within the manufacturing area of FBOs, and their directors are often part of the Board of Management. Furthermore, monitoring and verifying even minor details of in-house laboratories can be challenging, contributing to the controversy surrounding these facilities.

Despite these challenges however, the FSSAI has been proactive in addressing food testing laboratory issues in recent times. On February 14, 2023, the Food Authority announced that it had initiated the de-notification process of in-house testing laboratories of FBOs. The FSSAI has already taken action by denotifying the in-house laboratory of one of India’s biggest FMCG companies, ITC Foods at Guntur. Similarly, the Nutralytica Research Private Limited lab in Nashik has also been de-notified, with further action expected to be taken on other remaining in-house testing laboratories of FBOs in the future.

A lack of food testing labs accredited by the National Accreditation Board for Testing and Calibration Laboratories (NABL), is another significant issue in India’s food testing landscape. This problem was recently highlighted in Dakshina Kannada and Udupi districts of Karnataka where unsafe food has been causing health problems for students due to a shortage of NABL-accredited food testing labs. To address this issue FSSAI has been encouraging labs to obtain NABL-FSSAI Integrated Assessment Certification of Accreditation. However, according to FSSAI’s list of food testing laboratories published on March 9, 2023, approximately 90 out of 193 labs with valid NABL accreditation for testing do not possess NABL-FSSAI Integrated Assessment Certification of Accreditation. The authority is expected to take action on this matter in the near future.

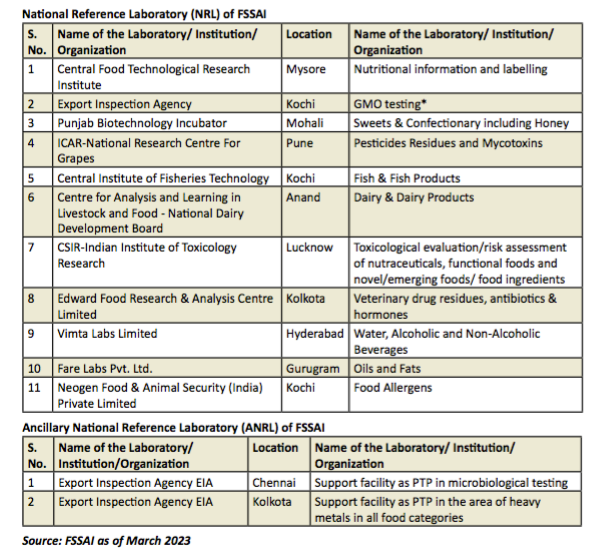

Given the challenges faced by the food testing labs in India, the FSSAI has been proactive in addressing the issue. While there may be varying opinions on FSSAI’s effectiveness in tackling food safety concerns in the country, many experts acknowledge the commendable job done by the authority in terms of improving food testing laboratories and related matters.

What’s happening in the field?

Food adulteration has been a major concern in India, with Nestle’s Maggi noodles and honey from established Indian brands such as Dabur and Patanjali being at the centre of some of the biggest controversies. However, with each such case, regulatory bodies like the FSSAI and other Indian authorities have been continuously upgrading laboratory standards and implementing new initiatives to ensure food safety.

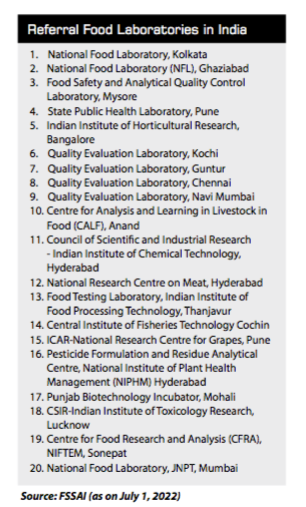

Recently, in order to strengthen testing infrastructure across the country, FSSAI advised states and union territories (UTs) to submit proposals for lab establishment and upgrades, with the offer of technical and financial assistance. Furthermore, States and UTs have been instructed to create positions for the recruitment of Designated Officers and Food Safety Officers (FSOs) and to fill any vacancies to bolster enforcement efforts in the country.

The government has been considering launching new labs for different food substances for a while now. For instance, the Union Minister for Agriculture and Farmers Welfare, Narendra Singh Tomar launched the Honey Testing Laboratory in Dimapur, Nagaland, which will aid beekeepers and processors in testing the honey produced. Recently, the Ministry of Youth Affairs and Sports (MYAS), FSSAI, and the National Forensic Sciences University (NFSU), Ahmedabad signed a Memorandum of Understanding (MoU) for establishing a testing facility for dietary supplements. The presence of undeclared compounds in the composition of dietary supplements is a serious concern. There is currently no testing facility available in India to ensure the absence of prohibited substances in dietary supplements.

Moreover, the Packaged Drinking Water Test Facility was also inaugurated at the National Test House (NTH) in Ghaziabad. With the addition of two pieces of equipment- Ultra High-Performance Liquid Chromatography (UHPLC) and Ion Chromatograph (IC), NTH-Ghaziabad has expanded its comprehensive quality testing facility for water. UHPLC aids in the quantification of different organic compounds, especially residual pesticides in drinking water samples.

In March, the FSSAI directed States and UTs to deploy mobile food testing vans called Food Safety on Wheels (FSW) to check adulteration of milk and milk products during the Holi festive season. Currently, there are 168 FSWs available with the States and UTs for carrying out on-the-spot food testing for various food products, including milk and milk products. The Milk-o-Screen system installed in FSWs can test for Fats, Solid-not-Fat, Protein, and Adulterants like Added Water, Urea, Sucrose, Maltodextrin, and Ammonium Sulphate.

Each FSW can test about 80 parameters qualitatively across seven different food categories. In addition, each FSW has a provision for performing simple microbiological tests if the states desire. The FSW is provided at a cost of ~ Rs 50 lakh each, including a recurring grant towards petrol, oil, lubricants and consumables.

In addition to government efforts to modernise the infrastructure and functionality of food testing labs, various entrepreneurs in the space have been innovating and contributing to these efforts. Some of the food testing labs such as Arbro Pharmaceuticals from New Delhi, Audentes Labs and Analytics from Mumbai, Doctors Analytical Laboratories Pvt Ltd from Navi Mumbai are looking at expanding their business operations and also updating their facilities by adding latest testing tools/ equipment.

Similarly in the public sector Centre for Food Research & Analysis (CFRA), set up by the National Institute of Food Technology Entrepreneurship and Management (NIFTEM), Sonepat in Haryana has been making efforts to become a self-sustainable centre of excellence of quality and safety of food through its services of global standards in areas of testing, inspection, certification analytical research etc. for all stakeholders of food including regulators, policy makers, consumers, industries etc.

Besides, it is trying to be a reliable support for stakeholders of quality and safety of food in India by being self-sustainable through its services of global standards in testing, quality assurance, analytical research and consultancy working as a referral lab and centre of excellence of food quality and safety.

Revamping infrastructure

Arbro Pharmaceuticals Pvt. Ltd., a Delhi-based laboratory specialising in spectroscopy, microscopy, chemical analysis, and instrumentation development, provides tailored, innovative solutions to food, pharmaceutical, and fine chemical companies. Talking about the lab, Saurabh Arora, Executive Director, Arbro Pharmaceuticals, highlighted that the laboratory has recently adopted several technology platforms for various stakeholders that will be operational in FY 23-24. They have successfully implemented ERP, TCS iON, Zoho CRM and field sampling, inspection, and audit from Hooper Labs to enhance service delivery efficiency.

The laboratory is poised for expansion throughout India. Presently, its Strategic Business Units (SBU) offering analytical testing services are located in Baddi-Himachal Pradesh, Bangalore-Karnataka, Manesar-Haryana, Delhi-NCR, and Bahadurgarh-Haryana. The expansion plans for testing services include increasing the capabilities and capacity of testing within the existing SBU and covering new geographies to offer services. Laboratories in the Baddi unit are being upgraded to offer full-fledged FSSAI-based Food and Nutraceutical testing, while currently servicing the pharma sector. The commercial offerings will begin by the end of the second quarter. Infrastructural improvements are being made at both the Delhi and Manesar units, which are being revamped to offer high-end regulatory services to food and pharma customers, respectively. In terms of expanding into new geographies, the testing facility is gearing up to set up labs in South India – Hyderabad, Western India – Mumbai, and Ahmedabad, Northern India – J&K and Himachal Pradesh, and East India – Sikkim.

Talking about the role of the regulatory authorities Arora said, “The role of FSSAI is to ensure that the food business operators (FBOs) produce safe and wholesome food that is available to consumers. FSSAI has been supporting laboratories through their recognition, based on the integrated assessment along with NABL. They have also enhanced the enforcement of Food Safety and Standards Regulations, which triggers samples for the laboratories, and conduct food safety surveillance programmes involving the notified laboratories in the testing process. This helps in identifying geographical ‘hotspots’ of misbranded, sub-standard and unsafe food.”

Expanding capacities and capabilities

Audentes Labs and Analytics provides testing services for a wide range of food and beverage products, including dairy products & analogues, fat, oils & fat emulsions, fruit & vegetable products, sweet & confectionery herbs, salt, spices, condiments & related products, cereal, pulses & their products, and more. With deep expertise in the field, the lab offers microbiological, biotechnological, chemical, residue, packaging material, and sensory evaluation services.

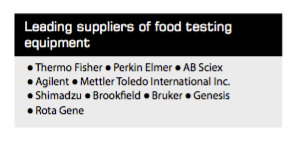

Audentes Labs has both capability and capacity to accommodate more than 50 samples per day for adulteration analysis of sweets. The lab’s high-end equipment are purchased from reputed vendors such as Agilent, Shimadzu, Perkin, AB Sciex, Brookfield, Bruker, Genesis, Rota Gene, Thermo Fisher, etc.

According to Dr Bindu Maurya, VP and Head of Laboratory Operations, Audentes Labs & Analytics, high-end equipment such as LCMS/MS, GCMS/MS, UHPLC, ICPMS, and RTPCR are in high demand in food testing. All the regulatory bodies such as FSSAI, APEDA, EIC, and FDA demand the use of these equipment for food analysis and development of new methods.

The lab is looking to expand its capacities and capabilities both geographically and sector-wise and continuously upgrade with the latest technology and tools to deliver quality products.

Dr Bindu further said “The food regulatory bodies in India are doing a commendable job in terms of keeping a check on the quality of products and have been continuously supporting the labs by providing technical training (online, offline) through the International Training Center for Food Safety & Applied Nutrition (ITFSAN) and The Quality Council of India (QCI).”

Expanding operations

Doctors Analytical Laboratories Pvt Ltd is a food testing laboratory headquartered in Navi Mumbai. It has recently been empanelled by the Spices Board for testing spices for metal contaminants. The lab has also recently validated and standardised a method for testing vegetable fat using HPLC with UV detection to check for adulteration in milk and milk products. It can carry out testing for up to 30 samples per day for vegetable fat. Moreover, it has established a method for testing ethylene oxide in seeds and spices. The lab is currently working on developing a test method for cannabidiol in hemp products to ensure label claims. Most of its equipment are purchased from AB Sciex, Agilent, Thermo Fisher, and Perkin Elmer.

According to Ashay Mehta, the Managing Director of Doctors Analytical Laboratories, the lab aims to expand its presence across the country by collaborating with small and medium-sized labs to improve turnaround time. It also plans to develop a library of testing methods in its Navi Mumbai laboratory that meets the regulatory requirements in India and globally. The lab aims to acquire accreditations and approvals from local and global regulatory bodies to establish acceptance of its test reports worldwide.

Speaking on the trends in the food testing space, Mehta said “I remember when we started in 2006, there was not much awareness or need for food testing in the domestic market. However, FSSAI has implemented various regulations that have made manufacturers, and consumers aware of the importance of food quality testing, leading to on-ground surveillance conducted by the FDA.”

Developing standards and protocols

The Centre for Food Research & Analysis (CFRA), based in National Institute of Food Technology Entrepreneurship and Management (NIFTEM), Haryana has an accredited state-of-art analytical laboratory with an integrated assessment from NABL, Agricultural and Processed Food Products Export Development Authority (APEDA) & FSSAI. CFRA not only carries out quality control analysis and certification of food products at different stages of the supply chain but also provides technical support related to analytical studies to food processing industries. It helps in developing standards and test protocols for various quality parameters essential for both raw and processed products for the domestic and international markets. CFRA also undertakes collaborative projects to provide solutions to the problems faced by the food industry, and academic research work.

Dr Komal Chauhan, Associate Professor at NIFTEM, said that CFRA has all the high-end sophisticated equipment such as LCMSMS, GCMS-MS, ICP-MS-MS, ICP-OES, AAS, HPLC, Ion chromatography, etc. With the help of these equipment and trained manpower, CFRA is able to strengthen research, devise new analytical methods, and ensure precision and validation. This has helped CFRA’s analytical capability to be highly diversified and provide support for policy formulation. CFRA is working closely with Confederation of Indian Industry (CII) as a data generation centre. The centre works end-to-end to deliver primary data for decision support for setting standards. The scope involves the selection of foods, parameters to be checked, collection of samples, analysis, opinion, report, and a status report. Initially, the centre is working on millets, and samples are collected from across India.

In the future, CFRA plans to expand its capacities and capabilities by becoming a decision support centre for policymakers, regulators, and industry by conducting policy research. CFRA is aiming to become a Reference Lab of FSSAI, and Food and Agriculture Organisation (FAO) to bring global recognition and develop as a Centre-of-Excellence in Training, Skill Development, and support for Codex.

The centre also imparts training in honey collection, testing, and certification of the quality of honey meant for exports, especially to European Union countries. Furthermore, CFRA supports the government sector in setting up food testing labs and upgrading their labs for NABL accreditation and integrated assessment.

Sharing her views on the role of FSSAI, Dr Komal Chauhan said, “The FSSAI and FDA have been very proactive in supporting and strengthening the referral and other state laboratories in terms of equipment, manpower, and training. Several schemes are available to provide support to these labs for upgrading their infrastructure along with sophisticated equipment, trained manpower for its operation, and maintenance for a limited period. Thereafter, these laboratories can apply for NABL accreditation for all the regulatory parameters to become self-sustainable. It is only through these organisations all the food testing labs in India are able to meet the global benchmark standards and practices and consistency in enforcement.”

Supporting the growth

While FSSAI and other food regulators in India have been putting considerable efforts into maintaining the quality of food in the nation, more collaborations between the government, industry and academia could take the Indian food sector to the next level. This could also enhance international businesses and exports of domestic companies.

The government has launched three central sector schemes, wherein financial assistance is provided to establish/upgrade Food Testing Laboratories to meet international standards i.e. ISO/IEC 17025/NABL. The three central sector schemes are (i) Food Safety and Quality Assurance Infrastructure implemented by the Ministry of Food Processing Industries, (ii) Strengthening of the Food Testing System in the Country including the provision of Mobile Food testing Lab implemented by Food Safety and Standards Authority of India under Ministry of Health and Family Welfare and (iii) Financial Assistance for Quality Development Scheme implemented by Agricultural and Processed Food Products Export Development Authority under Ministry and Commerce and Industries.

Although the government does not establish any Food Testing Laboratory on its own, proposals for food testing laboratories received are demand-driven. Hence, as per the demand in the particular location, new food testing labs have been adding up in the nation. With such schemes being implemented, the rate of service expansion of existing labs in different cities is also on the rise in the nation.

Moreover, according to Mordor Intelligence, a research organisation, the global analytical instrumentation market in food testing is anticipated to record a CAGR of 6.6 per cent during 2023- 2028 with Asia Pacific being the fastest-growing market. Looking at this scenario with fruitful government policies and industry interests, India’s food testing laboratories are set to fight the menace of food adulteration more efficiently.

Mansi Jamsudkar

(mansi.jamsudkar@mmactiv.com)